CAD – CAM

at ATUL, our designing facility has been completely modernized. We ensure that our designing excellence using CAD helps us to produce effective and accurate designs and it’s seamless integration with CAM technology makes complex machining simple with help of highly advanced tools like SolidWorks and Power Mill.

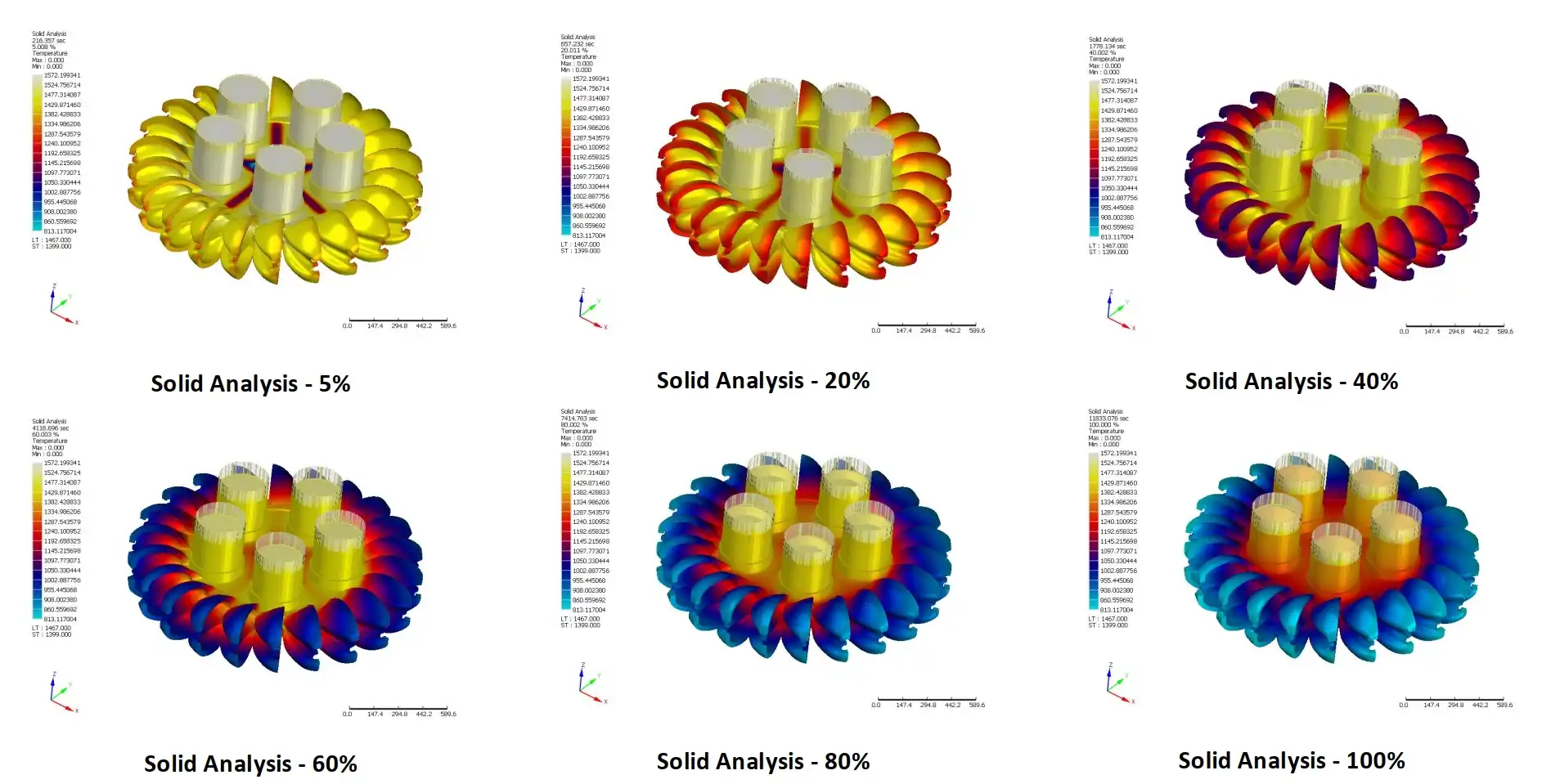

Casting Simulation

We have a powerful tool to visualize mold filling, solidification and cooling, and to predict the location of internal defects such as shrinkage porosity, sand inclusions, and cold shuts. It can be used for troubleshooting existing castings, and for developing new castings without shop-floor trials.

Alloy Selection and Product Redesign

We have in-depth knowledge of various alloys & well experienced design department which enables us to offer castings with enhanced metallurgy and design, which improvises application of redesigned component.

Reverse Engineering

We have the engineering & manufacturing expertise to reverse engineer your worn-out mechanical parts using laser scanners and portable FARO Arms and make new ones with similar or better efficiency.

Rapid Prototyping

Atul Precision cast can actualise your ideas and invention in just a few days which could give you opportunity to physically review the design and functionality of the product before it is sent for mass production with 3D Printing.

Our Advantages

Let's Experience Exclusive Quality

We are here to help you...